To achieve a perfect sheet in overflow weir leveling, you should use laser tricks that offer high accuracy and efficiency. Start by selecting a precise laser level and make sure it’s calibrated correctly. Set it up on a stable surface, align the beam with reference points, and monitor environmental factors like dust and vibrations. Regular calibration and proper alignment are crucial for reliable measurements. If you want to master these laser techniques, keep exploring to learn all the essential tips and tricks.

Key Takeaways

- Use high-precision laser levels calibrated regularly for accurate, consistent weir crest measurements.

- Secure laser equipment on stable, level surfaces to prevent misalignment during setup.

- Focus laser beams sharply on reference points to ensure clear, precise readings across the weir surface.

- Minimize environmental factors like dust, vibrations, and drafts that can affect laser accuracy.

- Follow safety protocols, including protective eyewear and secure equipment, to ensure reliable and safe measurements.

Understanding the Importance of Accurate Weir Leveling

Accurate weir leveling is essential because even small errors can substantially affect water flow measurements and overall system performance. Historically, methods relied on manual surveying techniques, which involved using spirit levels, rulers, and measuring tapes. These traditional approaches required careful, precise work, but they were often time-consuming and prone to human error. Precise leveling ensures that the crest of the weir is correctly aligned, which directly impacts flow calculations. When errors occur, they can lead to inaccurate flow readings, affecting water management and decision-making. Understanding the importance of accurate leveling underscores why modern tools, like laser techniques, are now replacing manual surveying to achieve higher precision and efficiency in weir installation and maintenance. Additionally, incorporating high-precision equipment like laser leveling tools can significantly reduce measurement errors and improve overall system reliability.

Limitations of Traditional Leveling Techniques

Traditional leveling techniques, such as using spirit levels, rulers, and measuring tapes, have long been the standard for setting weirs. However, they often fall short in complex situations like hydraulic modeling and sediment transport. Inaccuracies can lead to flawed data, affecting flow predictions and sediment management. Imagine trying to measure a shifting surface:

| Surface Type | Measurement Challenge | Resulting Error |

|---|---|---|

| Smooth Flow | Slight surface variations | Misaligned weir |

| Turbulent Flow | Rapid fluctuations | Inconsistent levels |

| Sediment Buildup | Obscured edges | Incorrect readings |

| Changing Water Levels | Dynamic conditions | Unreliable data |

These methods can’t adapt to the dynamic nature of weirs under fluctuating conditions. That’s where traditional techniques hit their limitations, especially when precise control is essential. Additionally, advanced measurement methods like laser leveling can provide the accuracy needed for complex weir setups.

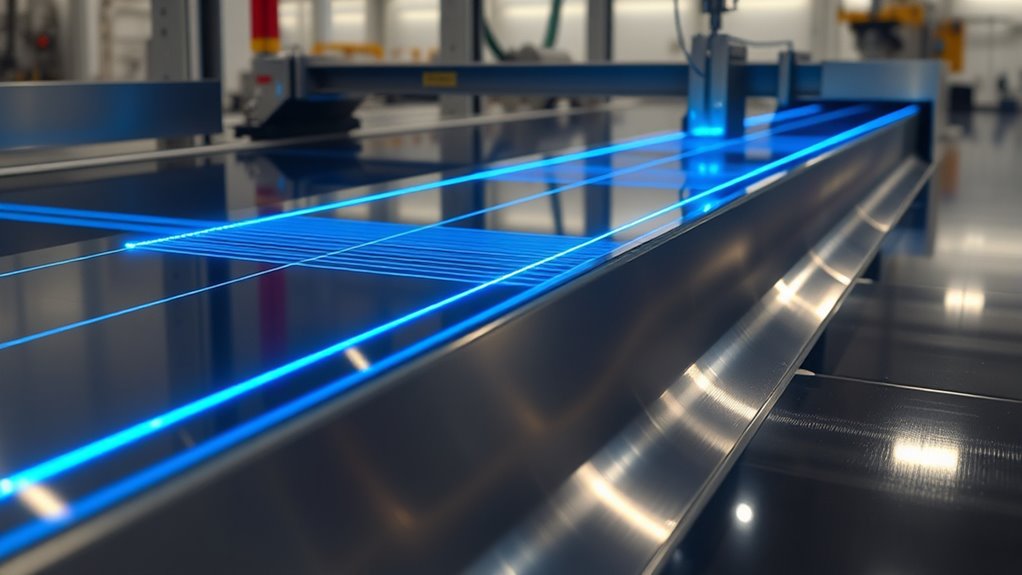

The Advantages of Laser Technology in Overflow Weir Measurement

Laser technology offers you precise measurements that traditional methods can’t match, reducing errors and ensuring accuracy. It also allows for quick data collection, saving you time during inspections. Plus, since it operates without contact, you avoid disturbing the structure or risking damage.

Enhanced Measurement Precision

By leveraging laser technology, measurement accuracy of overflow weirs is substantially enhanced. Laser calibration ensures your equipment maintains precise standards, reducing errors caused by manual adjustments. This method offers consistent, high-precision readings, even in challenging environments. Unlike traditional tools, lasers provide a direct, non-contact measurement approach, minimizing disturbance to the weir structure. The accuracy gained through laser calibration translates into reliable data, enabling you to make informed decisions about flow control and maintenance. With laser-based systems, you eliminate uncertainties associated with manual measurements, resulting in more consistent water level monitoring. This heightened measurement accuracy helps prevent over- or under-estimation of flow rates, ultimately optimizing system performance and ensuring safety. Laser technology’s precision guarantees your overflow weir measurements are both reliable and repeatable.

Rapid Data Collection

Utilizing laser technology allows for rapid collection of overflow weir data, considerably improving measurement efficiency. This speed benefits hydraulic modeling by providing quick, accurate data to analyze flow patterns and weir performance. It also helps assess sediment transport by capturing detailed surface profiles in less time. With laser systems, you can:

- Capture high-resolution measurements swiftly, reducing manual effort

- Obtain real-time data for immediate analysis and adjustments

- Minimize errors associated with traditional contact methods

- Streamline data integration into hydraulic models for better predictions

– Moreover, laser systems can ensure consistent measurement accuracy, which is crucial for reliable assessments. These advantages enable you to perform more frequent measurements, track changes over time, and optimize weir leveling processes, ensuring more precise control and better understanding of flow dynamics. Laser technology truly transforms overflow weir measurement into a faster, smarter process.

Non-Contact Operation

Non-contact operation offers significant advantages in overflow weir measurement by eliminating the need for physical contact with the structure. Using laser technology ensures you can measure the water level accurately without risking damage or disturbance to the weir. This method enhances safety, as laser devices are designed with laser safety features to prevent accidental exposure. Additionally, since lasers do not require contact, equipment calibration becomes more straightforward, maintaining measurement consistency over time. You avoid wear and tear on sensors and reduce maintenance costs. This non-intrusive approach allows for quick, precise readings in challenging environments, ensuring your measurements are reliable and safe. Laser technology’s non-contact nature streamlines operations while maintaining high safety standards and measurement accuracy. Incorporating safety precautions specific to laser use further enhances operational security and confidence in your measurements.

Essential Laser Tools and Equipment for Weir Leveling

To guarantee accurate weir leveling, having the right laser tools and equipment is essential. First, a laser level with precise calibration ensures your measurements are reliable. Second, invest in a laser receiver or detector to pinpoint the laser beam’s position over the weir. Third, use adjustable mounts or tripods for stable positioning, enabling consistent beam focusing. Fourth, a laser calibration tool helps verify the laser’s accuracy before each use, preventing errors. Proper beam focusing is critical for sharp, clear lines, reducing measurement inaccuracies. These tools work together to provide precise readings, making your leveling process more efficient and accurate. Additionally, understanding inspirational quotes about precision and dedication can motivate you to maintain high standards throughout your project. With the right equipment, you’ll achieve a perfectly leveled overflow weir, ensuring ideal operation.

Step-by-Step Procedure for Laser-Based Weir Leveling

To begin laser-based weir leveling, you need to make certain your equipment is properly set up. Focus on achieving accurate laser alignment to guarantee precise measurements. Once that’s done, you can proceed with the step-by-step process confidently. Ensuring your setup adheres to proper security features helps prevent unauthorized access during the operation.

Equipment Setup Essentials

Are you ready to guarantee accurate weir leveling with laser technology? First, set up your laser device on a stable, level surface, ensuring it’s properly calibrated by following calibration procedures. Next, consider environmental conditions: minimize dust, vibrations, and drafts that could affect readings. Then, align the laser beam precisely with the reference points, double-checking for consistency. Finally, verify the laser’s calibration with a known standard before starting measurements, maintaining awareness of environmental considerations throughout. This process ensures your equipment setup is accurate and reliable, forming the foundation for precise weir leveling. Proper setup minimizes errors and keeps your project on track, making laser technology your most effective tool for achieving a perfect sheet. Additionally, understanding space‑heating basics can help optimize your overall workflow and ensure consistent results.

Accurate Laser Alignment

Achieving precise laser alignment is essential for accurate weir leveling, and it begins with a systematic approach. First, perform laser calibration to ensure your equipment emits a true, consistent beam. Next, focus on beam alignment by positioning the laser so it projects a straight, stable line across the weir surface. Use a level or bubble indicator to confirm the laser’s horizontal accuracy. Adjust the laser mount carefully, ensuring it’s securely fixed to prevent shifts. Continuously check the beam’s alignment during the process, making small tweaks as needed. Proper laser calibration and meticulous beam alignment eliminate measurement errors, resulting in a perfectly leveled weir. This precision ensures smooth flow control and enhances the overall quality of your leveling operation. Regular use of Glycolic Acid may also assist in maintaining the equipment’s optimal condition by preventing buildup and ensuring clarity in laser components.

Common Challenges and How to Overcome Them With Laser Tricks

One of the main challenges in leveling overflow weirs is ensuring accurate measurements across uneven or complex surfaces. Laser tricks can help overcome this by addressing key issues:

- Cost considerations: Invest in high-quality laser equipment upfront to reduce long-term expenses from rework or errors.

- Environmental impacts: Minimize disturbance by using precise laser measurements, preventing unnecessary site disruptions and reducing waste.

- Surface irregularities: Use laser levels that adapt to uneven terrain, ensuring consistent readings despite surface complexity.

- Calibration and maintenance: Regularly calibrate lasers to maintain accuracy, avoiding costly mistakes and ensuring reliable data.

These tricks streamline the process, save money, and promote environmentally responsible practices during overflow weir leveling projects.

Ensuring Safety and Precision During Laser Measurements

To guarantee safety and precision during laser measurements, you must prioritize proper equipment handling and adherence to safety protocols. Always inspect your laser tools before use, ensuring they’re in good condition and functioning correctly. Follow safety protocols, such as wearing protective eyewear and keeping the work area clear of unnecessary personnel or obstructions. Accurate measurements depend on well-maintained equipment, so perform calibration procedures regularly to ensure the laser’s accuracy. Confirm the device’s calibration before each use, especially after any impact or long periods of storage. Precise readings rely on a stable setup, so secure all devices firmly and avoid unnecessary movement during measurement. Prioritizing safety and calibration minimizes errors and reduces the risk of accidents, ensuring smooth, reliable laser leveling operations. Additionally, staying informed about regulations, such as safety standards for laser equipment, is essential to maintain compliance and ensure safe usage.

Case Studies Showcasing Successful Laser-Leveling Applications

Numerous construction projects have demonstrated how laser leveling technology can dramatically improve accuracy and efficiency. Historically, this method replaced manual leveling, reducing errors and environmental impacts. In recent case studies, you see:

- A dam renovation where laser leveling ensured precise overflow weir alignment, minimizing ecological disruption.

- A flood control project that used laser-guided leveling to optimize water flow, reducing environmental disturbance.

- An urban infrastructure upgrade where laser tools sped up construction, cutting waste and energy use.

- A large-scale irrigation system that achieved perfect uniformity, supporting sustainable practices.

These examples highlight how laser leveling’s accuracy benefits both project success and environmental preservation. The historical context shows a shift toward cleaner, more efficient techniques, making laser technology a game-changer for hydraulic engineering.

Future Developments in Laser Technology for Hydraulic Engineering

Advancements in laser technology are poised to revolutionize hydraulic engineering further, building on the success of current laser leveling techniques. Future innovations will enhance laser calibration, ensuring even greater accuracy and consistency in applications like overflow weir leveling. As laser systems become more precise, you’ll find it easier to achieve perfectly level surfaces with minimal effort. New developments may include portable, user-friendly laser units that adapt to complex terrains, reducing setup time and increasing efficiency. Integration with automation and real-time feedback systems will allow for continuous adjustments during construction, improving quality control. These improvements will make laser technology more accessible and reliable, helping you achieve superior results in hydraulic projects while reducing errors and project timelines.

Frequently Asked Questions

How Does Ambient Light Affect Laser Measurement Accuracy?

Ambient light can considerably impact laser measurement accuracy by causing ambient interference, which reduces the device’s precision. It affects the laser’s light sensitivity, making it harder for your instrument to distinguish the laser beam from background light. To guarantee reliable readings, avoid bright or direct sunlight, and use laser equipment with good light sensitivity. Properly controlling ambient light conditions helps you achieve more accurate and consistent measurements.

What Is the Typical Calibration Process for Laser Leveling Equipment?

Calibration procedure is your secret weapon for perfect equipment accuracy, ensuring laser leveling tools perform flawlessly. You start by setting up the device on a stable, level surface, then use a known reference target or calibration plate. Adjust the laser according to the manufacturer’s instructions, checking readings against the reference. Regular calibration keeps your measurements precise, preventing errors that could rival cosmic chaos, and guarantees your laser equipment remains a beacon of precision.

Can Laser Tools Be Used in Outdoor or Windy Conditions Effectively?

Yes, you can use laser tools outdoors or in windy conditions effectively, but you need to take into account weather resistance and laser visibility. Wind can cause slight movements, so ensure your laser level has a sturdy mount and wind-resistant features. Good weather resistance helps protect the device from elements like rain or dust. To maintain visibility, choose laser models with high visibility beams and use target plates or glasses if lighting conditions are poor.

How Do Laser Tricks Improve Measurement Speed Compared to Traditional Methods?

Laser tricks critically boost measurement speed and efficiency compared to traditional methods. By using laser tools, you can quickly obtain precise, real-time data without manual readings or multiple setups. This reduces errors and saves time, allowing you to complete leveling tasks faster. The high measurement precision of lasers guarantees accurate results, making your work more efficient and reliable, especially in challenging outdoor conditions where speed and accuracy are vital.

What Maintenance Is Required to Keep Laser Equipment in Optimal Condition?

Did you know that proper maintenance can extend laser equipment lifespan by up to 30%? To keep your sensors in top shape, regularly perform sensor calibration to guarantee accuracy. Additionally, dust prevention is vital—use protective covers and clean lenses frequently to prevent dust buildup that can impair measurements. Staying proactive with these maintenance steps guarantees consistent performance, reduces downtime, and ensures your laser system continues delivering precise, reliable results.

Conclusion

By mastering laser tricks for overflow weir leveling, you’ll elevate your precision to an unparalleled level—almost as if you have the power to tame the entire hydraulic universe. Accurate measurements aren’t just a goal; they’re your secret weapon for flawless sheet construction. Embrace these cutting-edge tools and techniques, and watch your projects transform from good to legendary. With laser technology by your side, you’ll redefine what’s possible in hydraulic engineering—truly a game-changer.