To soundproof pumps and blowers for a quiet infinity pool room, start by identifying the main noise sources like vibrations or airflow. Use effective insulation materials such as mineral wool or dense mats, and build enclosures with sound-absorbing linings. Install vibration dampers and resilient mounts to reduce transfer. Regularly maintain and inspect your setup to keep noise levels low. If you want to discover more tips, continue exploring techniques for ideal quietness and comfort.

Key Takeaways

- Use sound-absorbing insulation like mineral wool inside enclosures to reduce noise from pumps and blowers.

- Install vibration isolators and resilient mounts to minimize mechanical vibration transmission.

- Enclose equipment in acoustically treated casings with sealed access points and acoustic vents.

- Incorporate mass-loaded vinyl barriers and double-wall designs to block sound escape.

- Schedule regular maintenance and monitoring to maintain effective noise reduction and prevent sound leaks.

Assessing Noise Sources and Soundproofing Goals

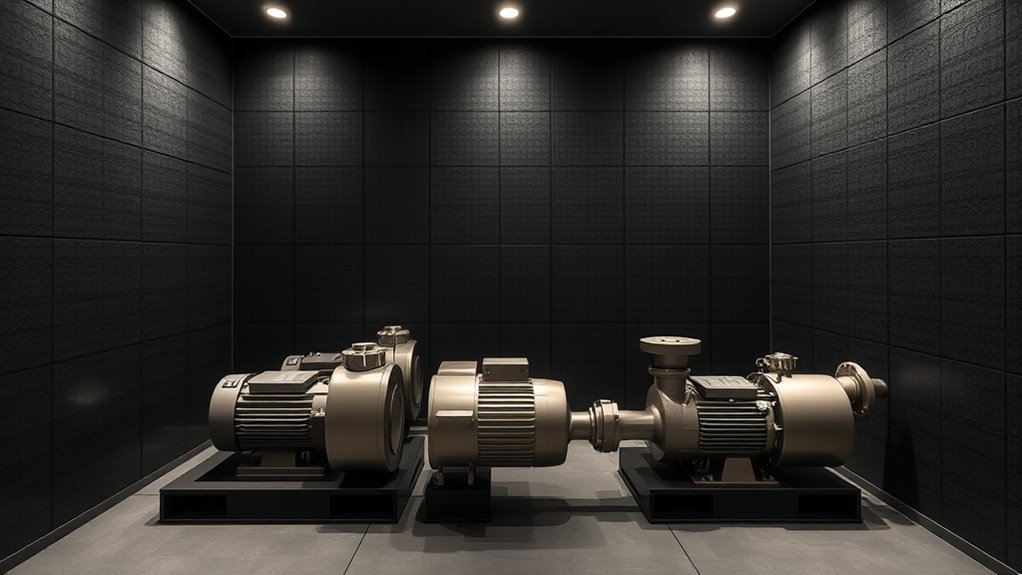

Before starting soundproofing efforts, you need to identify the primary noise sources from pumps and blowers. Pinpoint where the noise originates—whether it’s the motor, the vibration, or airflow. This helps you understand which components are loudest and require attention. Next, determine your soundproofing goals: do you want complete silence, or just a reduction to acceptable levels? Consider how noise affects the environment and your comfort. Measuring current sound levels with a decibel meter provides a baseline to evaluate success. Clarifying these goals early on ensures your soundproofing efforts are targeted and effective. Additionally, understanding the specific noise sources can guide the selection of appropriate soundproofing materials and techniques. Knowing where the noise comes from and what you aim to achieve guides your strategy, saving time and resources down the line.

Selecting Effective Insulation Materials for Pumps and Blowers

Choosing the right insulation materials is essential for effectively reducing noise from pumps and blowers. You need materials that absorb sound waves, dampen vibrations, and withstand environmental conditions. First, consider mineral wool or fiberglass batt insulation, which excels at sound absorption and heat resistance. Second, use mass-loaded vinyl sheets or dense mats to add mass and block sound transmission. Third, incorporate resilient mounting pads or vibration isolators to reduce mechanical vibrations reaching the enclosure. These materials work together to minimize noise leaks and vibration transfer, creating a quieter environment. Selecting the proper insulation guarantees your pump and blower noise stays contained, improving comfort and maintaining the serenity of your infinity pool room. Additionally, using soundproofing techniques can significantly enhance noise reduction efforts. Focus on these key materials for the most effective soundproofing results.

Designing Enclosures and Barriers to Contain Noise

Designing effective enclosures and barriers is essential for trapping noise generated by pumps and blowers. Start by selecting sturdy, sound-absorbing materials like mass-loaded vinyl or acoustic panels to line the interior surfaces. Confirm the enclosure has a tight seal to prevent sound leaks, especially around access points and ventilation openings. Incorporate double walls or staggered panels to disrupt sound transmission. Keep the enclosure slightly larger than the equipment to allow for insulation and airflow, reducing noise reflection. Ventilation should be carefully designed with sound baffles or acoustic louvers to minimize noise escape while maintaining adequate airflow. Properly designed enclosures considerably reduce noise levels, making your pool environment quieter and more comfortable. Additionally, paying attention to soundproofing techniques can further enhance noise reduction efforts.

Implementing Vibration Dampening Techniques

Vibration dampening is essential for reducing noise from pumps and blowers, as vibrations can transfer through mounting surfaces and amplify sound levels. To effectively minimize vibrations, you should:

- Use rubber or elastomeric mounts to absorb shocks and prevent vibrations from transmitting.

- Install resilient pads or mats beneath equipment to isolate vibrations from supporting structures.

- Incorporate flexible connections and mounting hardware to reduce direct contact and movement transfer.

- Selecting projectors with high-quality vibration resistance can further help maintain quiet operation and prevent unnecessary noise transmission.

Maintaining and Monitoring Soundproofed Systems

Regular maintenance and vigilant monitoring are essential to ensuring your soundproofed systems continue to perform effectively over time. You should schedule routine inspections to check for wear, loose fittings, or damaged components. Regularly clean filters and vents to prevent buildup that can reduce soundproofing effectiveness. Keep an eye on system performance metrics, such as noise levels and vibration patterns, to catch issues early. Use monitoring equipment to detect unusual sounds or vibrations that might indicate a problem. Document maintenance activities and system performance data to identify patterns or recurring issues. Promptly address any irregularities to prevent further damage or noise leakage. Proper planning and careful monitoring ensure your soundproofing remains effective, extending the lifespan of your systems and maintaining the tranquility of your infinity pool room.

Frequently Asked Questions

How Do Ambient Temperatures Affect Soundproofing Effectiveness?

Ambient temperatures directly impact soundproofing effectiveness by influencing material performance and air pressure. Warmer temperatures can cause materials to expand, potentially creating gaps that let sound pass through. Cooler temperatures may make materials contract, improving insulation but also risking cracks. You should consider maintaining a stable temperature environment to guarantee the soundproofing remains effective. Proper insulation, ventilation, and temperature control help keep noise levels low regardless of outside conditions.

Can Soundproofing Materials Impact Pump or Blower Performance?

Imagine a whisper-quiet oasis where your pumps hum softly, their performance unhindered. Soundproofing materials can slightly impact pump or blower efficiency if not chosen carefully, as dense barriers may restrict airflow or dampen vibration. However, quality soundproofing solutions are designed to balance noise reduction with ideal function, ensuring your infinity pool remains serene without sacrificing the power and performance you rely on.

What Are Cost-Effective Solutions for Small-Scale Pool Installations?

You can save money on small-scale pool installations by choosing affordable, effective soundproofing options like foam panels or mass-loaded vinyl. These materials are easy to install and reduce noise without adding much to your budget. Additionally, regular maintenance keeps equipment running smoothly, which prevents costly repairs. Installing a simple enclosure or barrier around your pump and blower also helps contain sound, making your pool area more peaceful without overspending.

Are There Eco-Friendly Soundproofing Options Available?

Like a gentle breeze calming a storm, eco-friendly soundproofing options do exist. You can opt for natural materials like cork, sheep’s wool, or recycled cotton, which absorb sound effectively and are sustainable. Green insulation panels made from recycled content also reduce noise without harming the environment. These options are not only kind to the planet but also provide a quiet, peaceful atmosphere for your infinity pool room.

How Long Does Soundproofing Installation Typically Take?

Soundproofing installation usually takes between a few days to a week, depending on the room’s size and complexity. You’ll want to plan for this timeframe to guarantee proper setup. During installation, contractors may need access to walls, ceilings, and floors, so prepare accordingly. Keep in mind, more extensive soundproofing or custom solutions could extend the timeline. Ultimately, a professional team can give you a precise estimate based on your specific needs.

Conclusion

By carefully evaluating noise sources and choosing the right materials, you create a peaceful oasis where sound naturally diminishes. Designing effective enclosures and dampening vibrations not only quiets pumps and blowers but also transforms your infinity pool room into a serene retreat. When maintenance aligns with monitoring, silence becomes a seamless part of your space. It’s no coincidence—your attention to these details ensures tranquility, making quietude an inevitable part of your luxurious pool experience.