Looking for the best peristaltic chemical feed pumps for your pool in 2025? I recommend models like the Blue White Flexflo A-100NA, Blue White Commercial A-100, and the Stenner Pump 85MJL5A3STAA. These pumps offer reliable, precise, and corrosion-resistant dosing perfect for maintaining pool chemistry. They range from compact to high-capacity options, suitable for different pool sizes and chemical needs. Keep exploring to find the ideal pump for your setup and guarantee consistent water quality.

Key Takeaways

- Look for pumps with adjustable flow rates and high dosing accuracy for precise pool chemical management.

- Prioritize models with corrosion-resistant materials and robust construction for long-term reliability.

- Consider pumps with digital controls, external interfaces (RS485, MODBUS), and calibration features for easy operation.

- Choose compact, easy-to-maintain pumps suitable for both residential and commercial pool setups.

- Ensure the pump supports high-pressure operation and chemical compatibility for safe, effective pool water treatment.

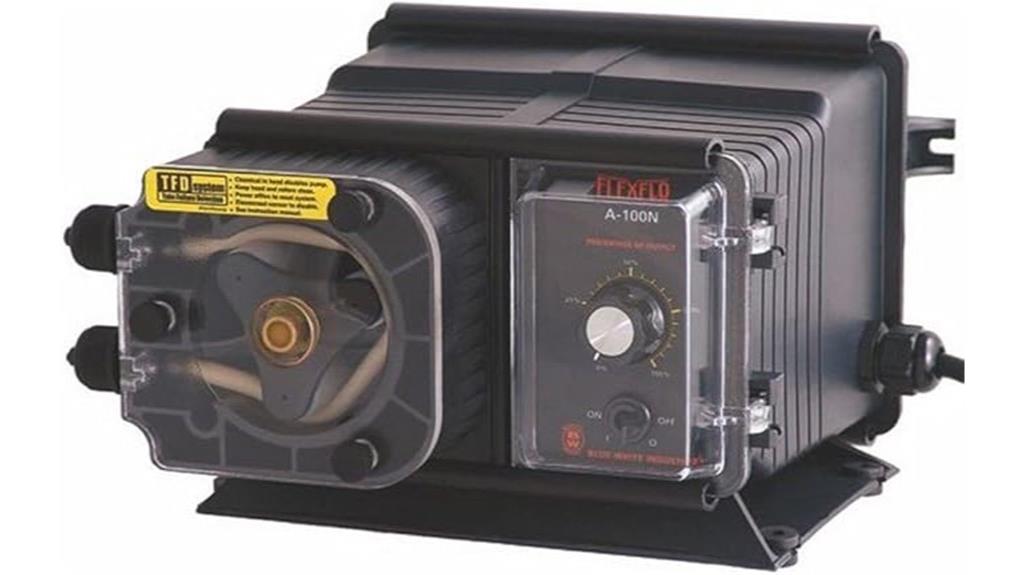

Pump, Peristaltic, Blue White Flexflo A-100NA, 115v,95.1 GPD

The Blue White Flexflo A-100NA is an ideal choice for pool owners and professionals who need a reliable, easy-to-maintain chemical feed pump. With its 115V power supply and a flow rate of 95.1 GPD, it guarantees consistent chemical dosing for your pool. Its compact design and lightweight build—just over 10 pounds—make installation simple. Built by Blue-White Industries, it’s suitable for above-ground setups and designed for industrial and scientific applications. Customers praise its dependability, and its straightforward operation makes it a top pick for maintaining excellent pool chemistry. Overall, the Flexflo A-100NA combines performance and ease of use in a durable package.

Best For: Pool owners and professionals seeking a reliable, easy-to-maintain chemical feed pump for consistent pool chemistry management.

Pros:

- Reliable operation with positive customer feedback on dependability

- Compact and lightweight design for easy installation and handling

- Suitable for above-ground setups and industrial applications

Cons:

- Limited flow rate of 95.1 GPD may not meet high-volume needs

- Only available with a 115V power supply, restricting use in regions with different voltages

- Limited information on advanced features or programmable options

Blue White FlexFlo A100N Metering Feeder Pump

If you’re looking for a reliable and easy-to-maintain solution for precise chemical dosing in pools, the Blue White FlexFlo A100N Metering Feeder Pump is an excellent choice. This peristaltic pump operates at 115V and delivers a flow rate of 6.8 GPD, ideal for small to medium pool applications. Its compact design, measuring just 1 inch in each dimension, makes installation simple, especially for above-ground setups. Made from durable plastic with compression nuts and a 3/8 OD connection, it’s built for consistent performance. Sold exclusively on Amazon, it’s backed by positive reviews and a 30-day return policy, ensuring peace of mind with your purchase.

Best For: pool owners and maintenance professionals seeking a reliable, easy-to-install chemical dosing pump for small to medium above-ground pools.

Pros:

- Compact and lightweight design for easy installation and space-saving setup

- Precise flow rate of 6.8 GPD ensures accurate chemical dosing

- Durable plastic construction with compression nuts for long-lasting performance

Cons:

- Limited flow capacity may not suit large or commercial pools

- Only available through Amazon, potentially restricting purchase options

- Requires 115V power supply, which may not be compatible with all setups

Blue White Commercial Chemical Feeder A-100 Peristaltic Pump 115V – A-145-6

For pool and hot tub owners seeking reliable chemical dosing, the Blue White Commercial Chemical Feeder A-100 Peristaltic Pump 115V – A-145-6 stands out as an ideal choice. This pump is designed for commercial chemical feeding, making it robust and dependable. It’s part of Blue White’s FlexFlo series, known for durability and ease of maintenance. With compact dimensions and a lightweight design, it’s easy to install and operate. Suitable for pools, hot tubs, and other applications, it offers consistent chemical delivery. Plus, with a manufacturer warranty and positive feedback, it’s a trusted option for maintaining precise and safe pool chemistry.

Best For: pool and hot tub owners seeking a reliable, easy-to-maintain chemical feeder for consistent and safe water chemistry management.

Pros:

- Durable and robust design suitable for commercial applications

- Compact and lightweight for easy installation and handling

- Supports precise chemical dosing to maintain optimal water quality

Cons:

- May require professional installation for optimal setup

- Limited to applications compatible with peristaltic pump operation

- Price point may be higher compared to smaller or residential models

Precision Controls Diaphragm Water Pump (31.6 GPD, 150 PSI, 115V)

When precise chemical dosing matters most, the Precision Controls Diaphragm Water Pump stands out as an ideal choice. It offers a flow rate of 31.6 GPD and handles up to 150 PSI, making it perfect for accurate chlorination and chemical feeding. Its digital stroke control and adjustable stroke length ensure reliable, consistent dosing. Made from durable plastic, it’s designed for longevity and easy installation, with components like tubing and check valves included. Operating on 115V, it’s versatile across various industries, including water treatment and environmental applications. This pump’s accuracy and durability make it a reliable tool for maintaining optimal pool chemistry.

Best For: DIY enthusiasts and professionals in water treatment, chemical dosing, or pool maintenance seeking a reliable, precise diaphragm pump for chemical feed applications.

Pros:

- Accurate flow rate of 31.6 GPD with high pressure capacity up to 150 PSI for precise chemical dosing.

- Easy to install and operate with adjustable stroke length and digital stroke control.

- Durable plastic construction ensures longevity and reliable performance in demanding environments.

Cons:

- Tubing included may require replacement over time due to wear.

- Slightly heavier at approximately 10 pounds, which may affect portability for some users.

- Limited to 115V operation unless hardwired for 230V, potentially requiring additional wiring adjustments.

Rola-Chem Pro Series Feed Pump RC-303-12 GPD 543811

The Rola-Chem Pro Series Feed Pump RC-303-12 GPD is an excellent choice for pool owners and maintenance professionals seeking precise chemical dosing. This digital peristaltic pump delivers 12 gallons per day, ensuring accurate chemical delivery to maintain healthy pool chemistry. Its compact size, measuring 10.5 x 10 x 10 inches, and lightweight design make installation straightforward. Built by ROLA-CHEM, it’s reliable and easy to operate, fitting seamlessly into existing pool systems. With proper setup—connecting to return lines and following flow directions—it provides consistent performance. Plus, its reputation as a best-seller indicates its popularity among users seeking dependable, precise chemical regulation.

Best For: pool owners and maintenance professionals seeking precise, reliable chemical dosing to maintain optimal pool chemistry.

Pros:

- Accurate chemical delivery with digital peristaltic pump technology

- Compact size and lightweight design for easy installation

- Reliable performance and user-friendly operation

Cons:

- Installation requires connecting to existing pool return lines and proper flow setup

- May need additional components or fittings for specific pool configurations

- Limited to 12 GPD, which might not suit larger or commercial pools

Precision Controls Diaphragm Water Pump (115V/115/230V)

Precision Controls’ Diaphragm Water Pump (115V/115/230V) stands out as an ideal choice for professionals needing accurate and reliable chemical dosing in water treatment and pool maintenance. Its high-precision design guarantees consistent liquid metering, with adjustable stroke and rate controls for precise dosing. Made of durable PVC, it handles corrosive liquids like chlorine and hydrogen peroxide effortlessly. Compact and easy to operate, it connects seamlessly to waterlines or PVC piping. Suitable for chlorination, chemical injection, and cooling towers, this pump offers versatile, long-term performance. Its universal voltage compatibility makes it adaptable for various setups, ensuring reliable, accurate chemical feeding in demanding environments.

Best For: professionals in water treatment, pool maintenance, chemical injection, and industrial environments needing precise and reliable chemical dosing.

Pros:

- High-precision metering with adjustable stroke and rate controls for accurate dosing.

- Durable PVC construction suitable for handling corrosive liquids like chlorine and hydrogen peroxide.

- Compact, easy to operate, and compatible with universal voltage (115V/230V) setups for versatile use.

Cons:

- May require additional accessories for hardwiring or specific plug adapters.

- Limited maximum pressure of 75 PSI, which might not suit very high-pressure applications.

- As with all chemical dosing pumps, regular maintenance is necessary to ensure optimal performance.

BT100LC-YZ1515x Peristaltic Pump for Chemical Liquids

If you’re looking for a reliable solution to dose and transfer chemical liquids accurately, the BT100LC-YZ1515x peristaltic pump is an excellent choice. It offers a flexible flow rate from 0.007 to 380 ml/min, making it suitable for various applications. The stainless steel housing guarantees corrosion resistance and easy cleaning, while the 3.5-inch touchscreen provides intuitive control. With multiple operation modes, calibration features, and external control options like RS485 and MODBUS, this pump delivers high precision and versatility. Whether used in labs or industrial settings, the BT100LC-YZ1515x guarantees consistent, accurate dosing of chemicals and liquids.

Best For: laboratories, biopharmaceuticals, and industrial users requiring precise chemical liquid dosing and transfer.

Pros:

- High precision with flow calibration feature ensures accurate dosing

- Wide flow rate range (0.007–380 ml/min) suitable for various applications

- Durable stainless steel housing provides corrosion resistance and easy maintenance

Cons:

- Viscous liquids like glycerin or honey may affect flow accuracy, requiring prior consultation

- External control setup (RS485, MODBUS) may need technical expertise

- Shipping costs and customs fees are the customer’s responsibility, which could increase total expenses

Stenner 45MHP2 Chemical Metering Pump Kit

For pool professionals and maintenance personnel seeking reliable chemical dosing, the Stenner 45MHP2 Chemical Metering Pump Kit offers precise flow control with adjustable settings from 0.2 to 3.0 GPD. Its durable design includes a clear pump head for easy visual checks and a quick-release mechanism for simple maintenance. Capable of running dry without damage, it’s ideal for chemical applications like sodium hypochlorite. With a maximum pressure of 100 PSI and compatibility with various chemicals, this heavy-duty pump ensures consistent, accurate dosing. Its compact size, robust construction, and ease of use make it a top choice for maintaining excellent pool chemistry.

Best For: pool professionals and maintenance personnel seeking precise, reliable chemical dosing for water treatment and pool chemistry management.

Pros:

- Adjustable flow rate from 0.2 to 3.0 GPD allows for precise control.

- Durable construction with a clear pump head for easy visual monitoring.

- Capable of running dry without damage, reducing maintenance and downtime.

Cons:

- Limited to a maximum pressure of 100 PSI, which may not suit all high-pressure applications.

- Requires AC power connection, limiting portability in some settings.

- Slightly heavier at 9 pounds, which might make installation less convenient for some users.

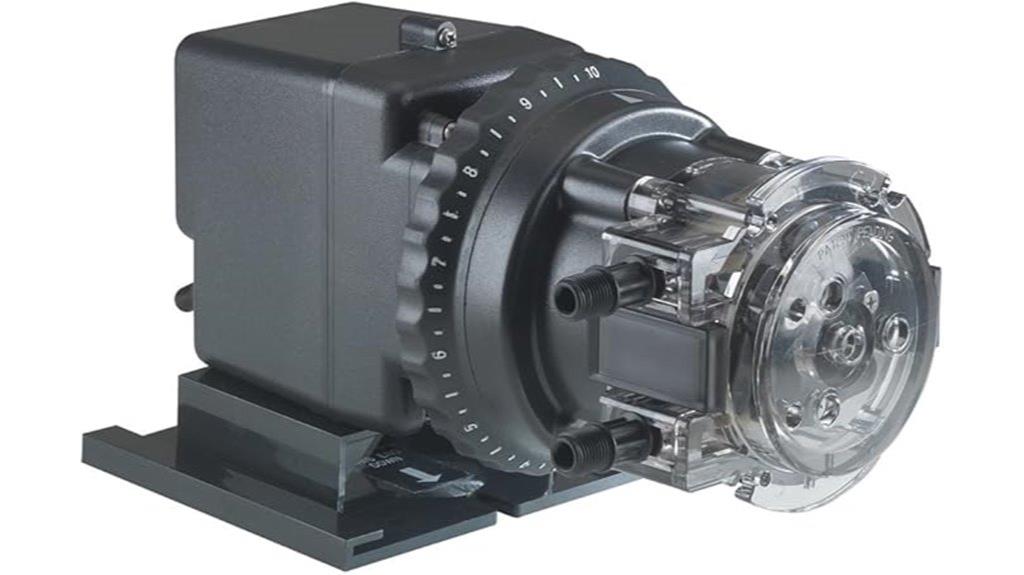

Stenner Peristaltic Pump 4.3-85 GPD, 25 PSI

The Stenner Peristaltic Pump 4.3-85 GPD, 25 PSI is an excellent choice for pool operators seeking a reliable, low-maintenance chemical feed solution. Its heavy-duty construction, with extra-thick tubing and corrosion-resistant parts, guarantees durability and long service life, often lasting a year without rupture. The pump offers smooth, consistent output with adjustable control, handling liquids with up to 50% solids. Its compact size and tool-free disassembly make installation and maintenance easy. Suitable for various applications, including pools, it operates unattended without clog-prone valves, making it an efficient, dependable choice for maintaining optimal pool chemistry.

Best For: Pool operators and water treatment professionals seeking a reliable, low-maintenance chemical dosing solution with durable construction and easy installation.

Pros:

- Heavy-duty, corrosion-resistant build ensures long service life and durability.

- Smooth, consistent output with adjustable control for precise chemical dosing.

- Compact and tool-free disassembly facilitate easy installation and maintenance.

Cons:

- Recommended tube replacement interval is six months, which may require frequent maintenance for some users.

- Maximum flow rate of 0.06 GPM might not suit very high-volume applications.

- No included anti-siphon valves; users may need additional components for certain setups.

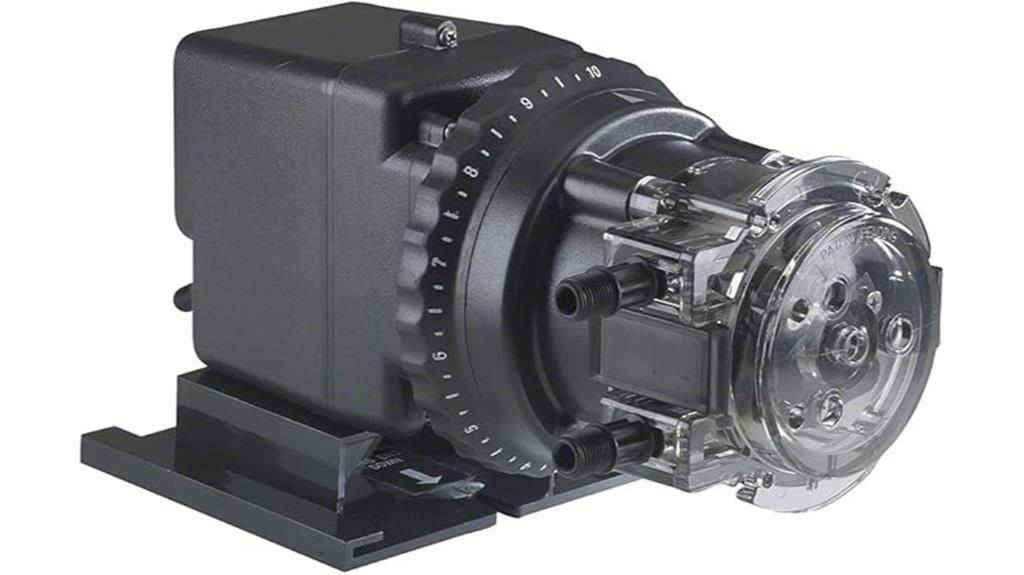

Stenner 85MHP17 Chemical Metering Pump Kit

The Stenner 85MHP17 Chemical Metering Pump Kit stands out as an excellent choice for pool owners and maintenance pros who need precise, reliable chemical dosing. It offers adjustable flow rates from 0.8 to 17 GPD across 10 settings, ensuring accurate chlorine or chemical delivery. Built with durable stainless steel and featuring a clear pump head, it allows easy visual flow checks. Its self-priming design and quick-release tube make maintenance straightforward. Powered by 220V AC, this pump is versatile for water treatment and industrial use, making it a dependable option for maintaining ideal pool chemistry with minimal fuss.

Best For: Pool owners and maintenance professionals seeking precise, reliable chemical dosing for water treatment and pool maintenance.

Pros:

- Adjustable flow rate from 0.8 to 17 GPD for accurate chemical delivery

- Durable stainless steel construction with a clear pump head for visual flow checks

- Easy maintenance with quick-release tube and self-priming design

Cons:

- Customer reviews indicate potential reliability issues over time

- Frequent tube replacements may be necessary for consistent performance

- Motor strain reported after extended use, possibly affecting longevity

Stenner Peristaltic Chemical Metering Pump Kit (Model 85MPH40)

If you need a reliable chemical dosing solution for pool maintenance, the Stenner Peristaltic 85MPH40 Pump Kit stands out with its precise fluid handling and durable design. It features a professional-grade build with a transparent head for easy visual monitoring, dual threaded inlet and outlet ports for secure tubing connections, and a compact size perfect for space-limited areas. Capable of running dry and self-priming, it delivers a steady flow rate of 40 GPD at 100 PSI, making it ideal for dosing chlorine and other chemicals. Its heavy-duty construction guarantees long-lasting performance, simplifying maintenance with tool-free tube replacement.

Best For: individuals or professionals needing precise chemical dosing for water treatment, swimming pools, or industrial applications in space-constrained environments.

Pros:

- Durable, professional-grade construction ensures long-lasting performance.

- Transparent pump head allows for easy visual inspection of fluid flow.

- Self-priming and capable of running dry, providing reliable and maintenance-friendly operation.

Cons:

- May require some technical knowledge for optimal installation and maintenance.

- Heavy-duty design could be more expensive than basic pump models.

- Limited flow rate options; fixed at 40 GPD at 100 PSI.

Precision Controls Diaphragm Water Pump (Hardwired, 63.36 GPD, 75 PSI)

For pool professionals seeking precise chemical dosing, the Precision Controls Diaphragm Water Pump stands out with its adjustable stroke and rate controls, ensuring accurate delivery of chlorine or other treatment chemicals. Its compact, durable design made of corrosion-resistant plastic makes it suitable for various industrial and pool applications. With a flow rate of 63.36 GPD and a maximum pressure of 75 PSI, it offers reliable performance for chlorination, chemical injection, or cooling towers. Easy to connect via PVC piping or waterlines, it operates on standard AC power and allows for easy adjustment to meet specific dosing needs, making it a versatile choice for maintaining ideal pool chemistry.

Best For: pool professionals and industrial users needing precise chemical dosing for chlorination, water treatment, and chemical injection applications.

Pros:

- Highly adjustable stroke and rate controls for accurate and customizable dosing.

- Durable, corrosion-resistant plastic construction suitable for aggressive liquids like chlorine.

- Compact size and easy connection options make installation and maintenance straightforward.

Cons:

- Requires a power source, limiting portability in remote locations.

- May need additional accessories or adapters for specific piping setups or voltage configurations.

- Not designed for high-volume applications beyond its specified flow rate.

Precision Controls Diaphragm Water Pump (31.6 GPD, 150 PSI, 230V)

When precise chemical dosing is critical, the Precision Controls Diaphragm Water Pump stands out as an ideal choice for pool maintenance and water treatment professionals. With a flow rate of 31.6 GPD and a pressure capacity of 150 PSI, it ensures accurate and reliable chemical delivery. Made from durable plastic and PVC, it’s built for long-term use in demanding environments. The pump features adjustable stroke length and digital stroke rate controls, allowing for fine-tuned dosing. Its compact design makes installation straightforward, and its components support continuous operation. Overall, it’s a dependable, exact solution for maintaining ideal pool chemistry.

Best For: pool maintenance and water treatment professionals needing precise, reliable chemical dosing in demanding environments.

Pros:

- Highly accurate flow rate of 31.6 GPD ensures precise chemical dosing

- Durable construction with PVC and plastic materials for long-term use

- Adjustable stroke length and digital stroke rate for fine-tuned operation

Cons:

- Requires 230V power supply, which may necessitate additional electrical setup in some locations

- Compact design may limit flow capacity for very large-scale applications

- Installation and calibration may require some technical knowledge for optimal performance

Blue-White BWA1N10A7T 0.25in OD 52.5 GDP Flexflo A100N Metering Feeder Pump

The Blue-White BWA1N10A7T 0.25-inch OD 52.5 GPD Flexflo A100N Metering Feeder Pump stands out as an ideal choice for pool owners and maintenance pros seeking reliable, precise chemical dosing. Its fixed speed operation and easy dial control make it simple to set and maintain accurate chemical flow rates. Made from durable plastic, it’s suitable for above-ground setups and doesn’t require bypass valves, reducing vapor lock risk. With a self-priming feature and a flow rate of 52.5 GPD, it ensures consistent dosing without constant supervision. This pump combines ease of use with dependable performance, making it a smart addition to your pool chemistry management.

Best For: Pool owners and maintenance professionals seeking reliable, precise chemical dosing with easy operation and maintenance.

Pros:

- Fixed speed operation with simple dial control for accurate flow rate adjustment

- Self-priming design prevents vapor lock and ensures consistent priming against maximum pressure

- Durable plastic construction suitable for above-ground installations and resistant to corrosion

Cons:

- Limited to a flow rate of 52.5 GPD, which may not meet higher demand applications

- Fixed speed operation offers less flexibility compared to variable speed pumps

- Requires AC or AC/DC power sources, which may limit portability in certain settings

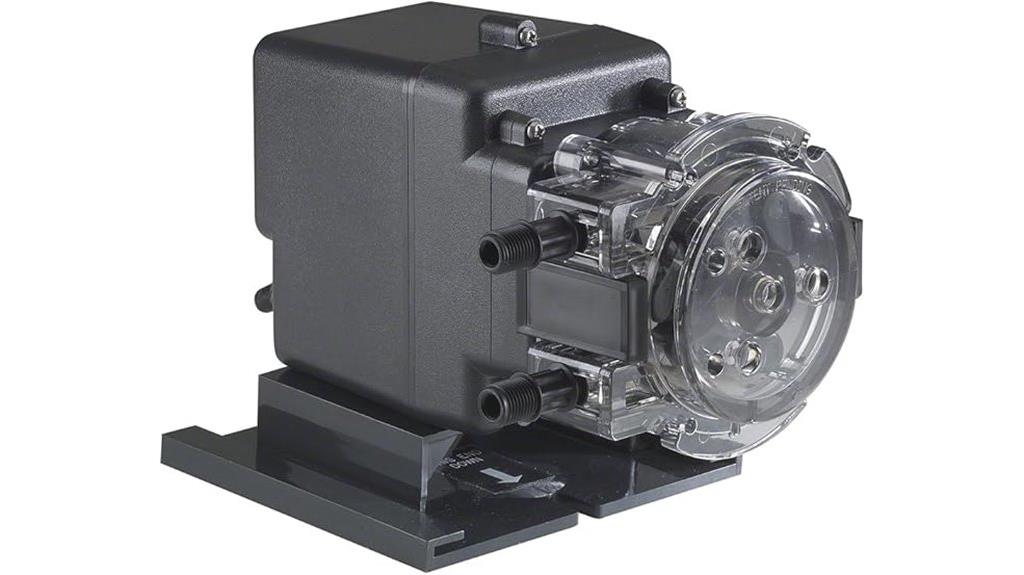

Stenner Pump 85MJL5A3STAA Peristaltic Pump

The Stenner Pump 85MJL5A3STAA stands out as an ideal choice for pool owners and professionals seeking reliable chemical feed solutions. Its peristaltic design with a 120V motor and #5 Santoprene tubing ensures consistent, precise dosing. The pump is self-priming up to 25 feet and can run dry without damage, reducing maintenance concerns. Its adjustable feed rate from 5% to 100% allows for fine-tuning chemical levels. Easy to service with tool-free sub-assemblies, it adapts quickly to different pool needs. Overall, this pump combines durability, flexibility, and ease of use for maintaining excellent pool chemistry.

Best For: pool owners and professionals seeking a reliable, easy-to-maintain chemical feed pump for consistent water chemistry management.

Pros:

- Self-priming up to 25 feet and capable of running dry without damage, reducing maintenance.

- Adjustable feed rate from 5% to 100% for precise chemical dosing.

- Tool-free sub-assemblies allow for quick service and easy conversion to other models.

Cons:

- Requires a 120V power supply, which may limit installation options in some locations.

- Peristaltic tubing may need replacement over time depending on chemical compatibility and usage.

- May be more costly upfront compared to simpler or less adjustable pumps.

Factors to Consider When Choosing a Peristaltic Chemical Feed Pump for Pools

When selecting a peristaltic chemical feed pump for your pool, you’ll want to take into account several key factors. These include the pump’s flow rate, chemical compatibility, power needs, durability, and how easy it is to maintain. Focusing on these points ensures you choose a pump that’s reliable and perfectly suited to your pool’s needs.

Pump Flow Rate

Choosing the right pump flow rate is essential because it directly impacts how effectively your pool receives the necessary chemicals. If the flow rate is too low, your pool may not get the proper chemical balance, leading to issues like algae growth or cloudy water. Conversely, a flow rate that’s too high can cause overdosing, wasting chemicals and potentially damaging your pool components. It’s important to match the pump’s flow capacity to your pool’s chemical needs, which usually range from 6.8 to 95.1 gallons per day depending on size and requirements. Make sure the pump can handle peak demands without losing prime or performance. Precise control over flow adjustments helps you fine-tune chemical delivery, ensuring your pool stays balanced and water quality remains ideal.

Chemical Compatibility

Selecting a peristaltic chemical feed pump requires careful attention to chemical compatibility to guarantee reliable operation and long-lasting performance. I always check that the tubing material suits the chemicals I use, like Santoprene for chlorine or Viton for aggressive solvents. It’s crucial to verify that the pump’s materials resist the specific pH and corrosiveness of my pool chemicals to prevent degradation. I also ensure the tubing and internal components are rated for the chemical’s concentration and temperature, which helps avoid damage and extends lifespan. Consulting the manufacturer’s chemical compatibility chart is a smart step to confirm suitability. Additionally, I consider whether the pump can handle viscous or reactive chemicals without clogging or breakdown, ensuring consistent, trouble-free dosing for my pool’s chemistry.

Power Requirements

Have you checked that the pump’s voltage matches your power supply? Confirming the correct voltage—such as 115V or 230V—is vital to prevent electrical issues and guarantee safe operation. Find out if the pump needs a simple plug-in connection or if it’s designed for hardwiring, especially if continuous operation is required. Consider your electrical capacity to make sure the pump’s power consumption won’t overload your circuits. Some pumps feature adjustable speed or stroke rate settings, which can influence overall power needs; choosing one with adjustable features might help optimize energy use. Finally, verify that the pump’s electrical components and wiring comply with local standards and safety codes to avoid hazards. Proper attention to power requirements guarantees reliable, safe performance for your pool’s chemical dosing system.

Pump Durability

When evaluating peristaltic chemical feed pumps for pool use, durability is a key factor that can’t be overlooked. I look for pumps with high-quality, corrosion-resistant tubing and housing materials that withstand prolonged chemical exposure. Heavy-duty construction with reinforced components and robust fittings is essential to prevent wear and damage during continuous operation. I also consider pumps that can run dry without damage, ensuring they stay operational if the chemical supply is interrupted. Long service life is supported by features like quick-release tubing, making maintenance and replacements quick and easy, which minimizes downtime. Additionally, pumps with proven resistance to clogging and material degradation help maintain consistent performance over time, ensuring reliable chemical dosing for safe, balanced pool chemistry.

Ease of Maintenance

Ease of maintenance is essential when choosing a peristaltic chemical feed pump for pools, as it directly affects operational efficiency and downtime. I look for pumps with quick-release or tool-free pump heads, which make tube replacement and routine checks straightforward. Choosing models with durable, corrosion-resistant materials like reinforced plastic or stainless steel helps them withstand harsh chemicals and extend lifespan. It’s also important to select pumps with easy access to internal components for cleaning and inspection without disassembly tools. Visual flow indicators or clear pump heads allow me to monitor operation easily, spotting blockages or leaks early. Additionally, adjustable flow rates and stroke settings give me control over maintenance procedures, ensuring consistent chemical dosing and reducing the need for frequent adjustments.

Control Features

Selecting a peristaltic chemical feed pump with the right control features is crucial for maintaining accurate and reliable chemical dosing in pools. Adjustable stroke and flow rates are essential for precise control, ensuring the right chemical levels every time. Digital controls with digital stroke rate and variable stroke length offer higher accuracy and make calibration straightforward. External control options like high/low level triggers, RS485, or MODBUS enable seamless integration into automated pool systems, enhancing efficiency. While simple manual controls such as dial knobs are convenient for quick adjustments, they lack the precision of digital interfaces. Preset configurations and calibration functions are also valuable, helping to maintain consistent chemical feed over time and reducing the need for constant manual oversight.

Size and Space

Choosing the right size and space for a peristaltic chemical feed pump is essential to guarantee smooth installation and maintenance. It’s important to confirm the pump’s dimensions fit within your available area, considering both height and footprint. If space is limited, opt for a compact model around 8 to 10 inches in length and width. Decide between above-ground or below-ground units, as above-ground pumps often need less space but require extra clearance for servicing. Ease of maintenance is critical, so select a pump that allows easy tubing replacement and straightforward access for repairs. Additionally, make sure the pump’s size accommodates your piping connections and supports proper flow routing within your pool setup to prevent installation issues or operational disruptions.

Cost Effectiveness

When evaluating peristaltic chemical feed pumps for pool applications, considering cost effectiveness helps guarantee you get value over the long run. I always assess both the initial purchase price and ongoing maintenance costs, like tubing replacements and repairs. Choosing pumps made from durable materials reduces downtime and the frequency of replacements. Adjustable flow rates and easy calibration features help assure precise chemical dosing, which minimizes waste and saves money. I also compare energy consumption, as models with lower power requirements can lead to substantial savings over time. Additionally, I look into the availability and costs of consumables such as tubing and seals, since these impact operational expenses. Prioritizing these factors guarantees you select a pump that balances upfront cost with long-term savings and reliability.

Frequently Asked Questions

How Do I Calibrate a Peristaltic Pool Chemical Feed Pump?

To calibrate a peristaltic pool chemical feed pump, I start by turning off the pump and disconnecting the tubing. Then, I set the pump to run for a specific time, like a minute, and measure how much chemical it dispenses. I adjust the calibration dial or setting until the pump delivers the correct amount per cycle. Afterward, I reconnect everything, turn it on, and verify the output.

What Maintenance Is Required for Long-Term Pump Reliability?

To keep my peristaltic pump reliable for the long haul, I ensure I regularly inspect the tubing for wear, replace it as needed, and keep the pump clean. I also check the rollers and motor to prevent any jams or overheating. It’s tempting to ignore routine maintenance, but I’ve learned that staying on top of these small tasks prevents costly breakdowns and keeps my pool chemistry perfectly balanced.

Can These Pumps Handle Different Chemical Viscosities Safely?

Yes, these pumps can handle different chemical viscosities safely. I’ve found that peristaltic pumps are versatile because I can adjust the roller compression and tubing size to match the chemical’s viscosity. I always guarantee I select the right tubing material and set the flow rate appropriately. This way, I maintain safe, reliable chemical dosing without risking damage or inaccurate feed, no matter the viscosity.

Are There Safety Features to Prevent Over-Chemical Dosing?

Yes, many peristaltic chemical feed pumps come with safety features like built-in flow monitors and adjustable dosing controls to prevent over-chemical dosing. I always recommend choosing a model with automatic shut-off or alarms that activate if the chemical levels surpass safe limits. These features help me guarantee safe, accurate chemical delivery, protecting both my pool and my family from potential hazards.

How Do Environmental Conditions Affect Pump Performance?

Environmental conditions can greatly impact pump performance. I’ve noticed that extreme temperatures can cause materials to expand or contract, affecting seals and tubing. High humidity might lead to corrosion, and exposure to direct sunlight can degrade plastic parts over time. To keep my pump running smoothly, I make sure it’s installed in a shaded, sheltered area and regularly inspect for signs of wear or damage caused by environmental factors.

Conclusion

Choosing the right peristaltic pump is like finding the perfect heartbeat for your pool’s chemistry. When you pick a reliable, well-suited pump, it keeps your pool’s essential signs steady and clear as a summer sky. Trust your instincts, consider the factors, and let your pool breathe easy. With the right pump in your corner, you’ll keep that sparkling oasis healthy and vibrant all year long—like a well-orchestrated symphony.