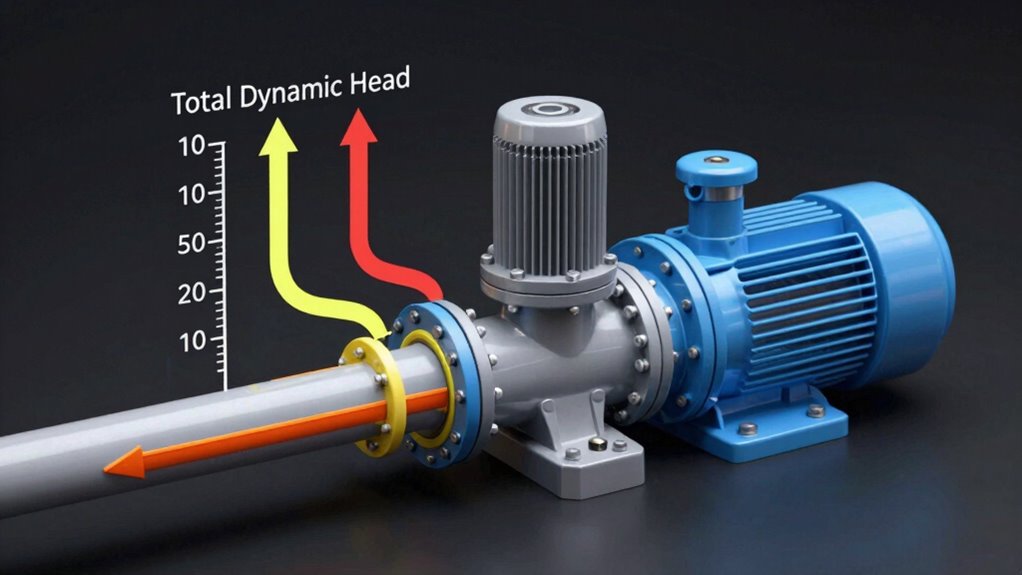

Total Dynamic Head (TDH) is the key number you need to select the right pump. It measures how much effort your pump must exert to move water through pipes, fittings, and elevation changes. Factors like friction, pipe size, and height affect this value. Knowing your TDH helps you choose a pump that’s efficient, reliable, and properly suited to your system. If you keep exploring, you’ll find practical tips to accurately calculate and optimize your pump setup.

Key Takeaways

- Total Dynamic Head (TDH) quantifies the effort needed to move water through a system, guiding pump selection.

- It includes static lift, elevation changes, and pipe friction losses affecting system performance.

- Accurate TDH calculation ensures the pump can meet flow and pressure requirements efficiently.

- Overestimating or underestimating TDH can lead to inefficient operation or equipment failure.

- Using proper measurement tools and formulas helps determine the correct TDH for optimal pump choice.

What Is Total Dynamic Head and Why Is It Important?

Have you ever wondered how to determine the true effort needed to move water through a pump system? Total Dynamic Head (TDH) is the key measurement that captures this effort. It accounts for the energy required to push water through pipes, fittings, and equipment. Understanding TDH helps you select a pump that matches your system’s demands, ensuring ideal pump efficiency. A well-designed system minimizes unnecessary energy use by reducing system losses and aligning with proper pump specifications. Recognizing what contributes to TDH enables you to optimize performance, save energy, and extend equipment lifespan. Properly assessing system head requirements is crucial for achieving optimal pump operation and efficiency. Knowing how to measure and evaluate system losses allows for better pump selection and system troubleshooting. Additionally, understanding pump curve characteristics can help you match the pump’s performance to your specific needs for maximum efficiency and longevity. Considering energy consumption factors also plays a vital role in designing a sustainable and cost-effective pumping system.

Understanding Elevation, Friction, and System Losses in TDH

Elevation changes can important affect the total dynamic head you need to consider. Friction from pipes and fittings adds to system losses, requiring more power to maintain flow. Understanding these factors helps you design efficient systems that account for real-world conditions. Additionally, considering grocery savings strategies can help in other areas of planning and resource management. Recognizing how system components contribute to overall head loss allows for better pump selection and energy efficiency. Moreover, accounting for water flow resistance ensures your system operates optimally under varying conditions. Being aware of system design principles can further optimize pump performance and reduce operational costs. For example, selecting appropriate pipe diameters and minimizing unnecessary fittings can significantly decrease system friction.

Elevation Impact on TDH

Understanding how elevation affects total dynamic head (TDH) is essential because as the height of your system increases, the pump must work harder to overcome the vertical distance, adding to the overall head required. When you lift water to higher elevations, you increase the static head, which directly impacts pump performance. This means you’ll need a pump with sufficient capacity to handle the increased load, especially during system troubleshooting or maintenance. If the elevation change isn’t properly accounted for, your pump may struggle or fail prematurely. Regular pump maintenance helps guarantee it operates efficiently under these conditions. By understanding elevation’s role, you can select the right pump size and prevent issues caused by insufficient head, ultimately improving system reliability and longevity. Additionally, considering system losses such as friction and fittings will ensure an accurate assessment of the total dynamic head needed for optimal operation. Recognizing elevation effects as part of your system analysis is crucial for selecting the appropriate pump and ensuring long-term performance.

Friction Loss Factors

Friction losses within a piping system can markedly impact the total dynamic head (TDH) you need to contemplate when designing or troubleshooting a pump setup. These losses depend on the pipe’s friction coefficient, which varies based on pipe material and condition, and the pipe diameter. A smaller diameter increases friction, raising the head loss, while a larger diameter reduces it. As water flows through the pipe, friction causes pressure drops, requiring more energy from the pump. To accurately estimate these losses, you’ll use formulas that incorporate the friction coefficient and pipe diameter. Recognizing how these factors influence system resistance helps you select a pump capable of overcoming friction losses efficiently, ensuring consistent flow and preventing system strain. Additionally, understanding system resistance is crucial for optimizing pump performance and energy efficiency. Friction loss calculations enable precise pump sizing, which is essential for system reliability and cost-effectiveness. Moreover, considering pipe roughness can further refine your estimates of friction losses, leading to more accurate pump selection.

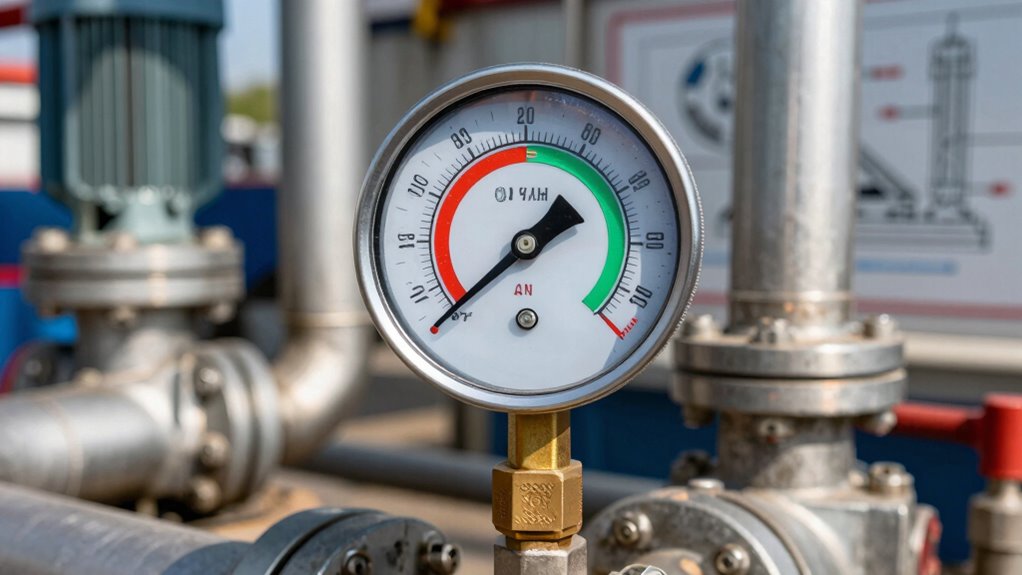

How to Measure Total Dynamic Head in Your Pump System

Measuring the total dynamic head (TDH) in your pump system is essential for ensuring ideal performance. Accurate measurement helps optimize pump efficiency and confirms your system calibration. To do this effectively:

Measuring TDH ensures optimal pump performance and system calibration.

- Use a manometer or pressure gauge at the pump discharge and suction points

- Measure static and dynamic pressure readings under normal operating conditions

- Record flow rates simultaneously for consistency

- Make certain gauges are calibrated correctly for precise results

- Consider environmental factors that might influence pressure readings

- Refer to deep-sky imaging system guidelines to understand how pump performance impacts overall setup efficiency

- Applying test procedures from industry standards can improve measurement reliability.

Step-by-Step Guide to Calculating TDH

Have you ever wondered how to accurately determine the total dynamic head (TDH) of your pump system? Calculating TDH is essential for proper pump sizing and effective system design. To start, measure the vertical lift from the fluid source to the discharge point, which accounts for elevation changes. Next, assess the system’s friction losses, which depend on pipe length, diameter, and fittings. Add these together to get the static head and friction head. Don’t forget to include any additional pressure requirements. The sum of these components gives you the total dynamic head. Properly understanding system hydraulics ensures you select a pump that meets your needs without overloading or underperforming. It’s also important to consider variations in fluid properties, such as viscosity or temperature, that can affect head calculations. For accurate results, use appropriate measurement tools and formulas to refine your calculations. Additionally, accounting for real-world conditions like unexpected pressure drops can help ensure reliability. Understanding fluid dynamics can further optimize your system’s efficiency and longevity.

How Elevation and Friction Losses Impact Your Pump Choice

Since elevation changes and friction losses directly affect the energy needed to move fluid through your system, understanding their impact is crucial for selecting the right pump. Elevation increases the total dynamic head, requiring a pump capable of overcoming vertical lift. Friction losses, influenced by pipe diameter and fluid viscosity, cause pressure drops along the piping. Smaller pipe diameters and higher fluid viscosity amplify these losses, demanding a more powerful pump. To optimize your choice, consider:

- The height difference in your system’s elevation profile

- Pipe diameter and material affecting friction losses

- Fluid viscosity and its impact on flow resistance

- Length and complexity of piping runs

- Desired flow rate and efficiency goals

Accurately accounting for these factors ensures your pump handles elevation and friction losses effectively, preventing system inefficiencies or failures. Additionally, understanding how total dynamic head integrates all these elements helps in selecting a pump that maintains optimal performance across varying conditions.

How Total Dynamic Head Affects Pump Performance and Efficiency

Total Dynamic Head (TDH) directly impacts how well your pump performs and how efficiently it operates. If TDH is too high, your pump works harder, reducing pump efficiency and increasing energy costs. Conversely, a lower TDH than needed can cause insufficient flow, risking system failure. To enhance performance, select a pump rated for the correct TDH. Consider this comparison:

| Pump Type | Efficiency Impact | System Optimization |

|---|---|---|

| Under-sized | Low efficiency, overload | Poor flow, system strain |

| Correct size | Max efficiency | Optimal performance |

| Over-sized | Energy waste, cost | Excess capacity, unnecessary |

Understanding how TDH affects pump operation helps you choose equipment that balances efficiency and system needs, saving energy and ensuring reliable performance.

Common Mistakes When Calculating or Considering TDH

Many people forget to account for friction losses in pipes, which can substantially reduce pump efficiency. Ignoring system elevation changes can also lead to incorrect TDH calculations, causing undersized or oversized pumps. To avoid these mistakes, you need to consider all factors that impact system head accurately.

Overlooking Friction Losses

Friction losses often get overlooked when calculating or considering total dynamic head because they might seem minor compared to other factors. However, pipe resistance caused by friction markedly impacts your pump’s performance, especially at higher flow rates. Ignoring these losses can lead to undersized pumps or system failures. To accurately account for friction:

- Consider the pipe material and diameter

- Calculate the flow rate’s effect on resistance

- Use proper friction loss formulas

- Include fittings, elbows, and valves

- Remember that longer pipes increase resistance

Ignoring System Elevation

Ignoring system elevation changes is a common mistake that can considerably underestimate the total dynamic head. Elevation impacts pressure drop, especially when pumps need to lift water to higher levels. Failing to account for this can lead to selecting a pump with insufficient capacity. Additionally, pipe diameter influences pressure drop; smaller diameters increase pressure loss, especially over elevation gains. When you overlook these factors, your calculations become inaccurate, risking inadequate flow or pump failure. Always include elevation head in your TDH calculations, especially if your system involves significant vertical movement. Remember, even a few feet of elevation can make a big difference in total head requirements. Properly considering elevation ensures your pump operates efficiently and reliably, preventing costly undersizing or oversizing.

How to Choose the Right Pump Based on Your TDH Needs

Choosing the right pump starts with understanding your Total Dynamic Head (TDH) requirements. Once you’ve calculated your TDH, you can select a pump that meets your system’s needs efficiently. To do this effectively:

- Compare pump specifications to verify they match your calculated TDH

- Confirm system compatibility for seamless operation

- Focus on flow rate capacity alongside head requirements

- Consider energy efficiency to reduce operational costs

- Evaluate durability and material compatibility with your fluid type

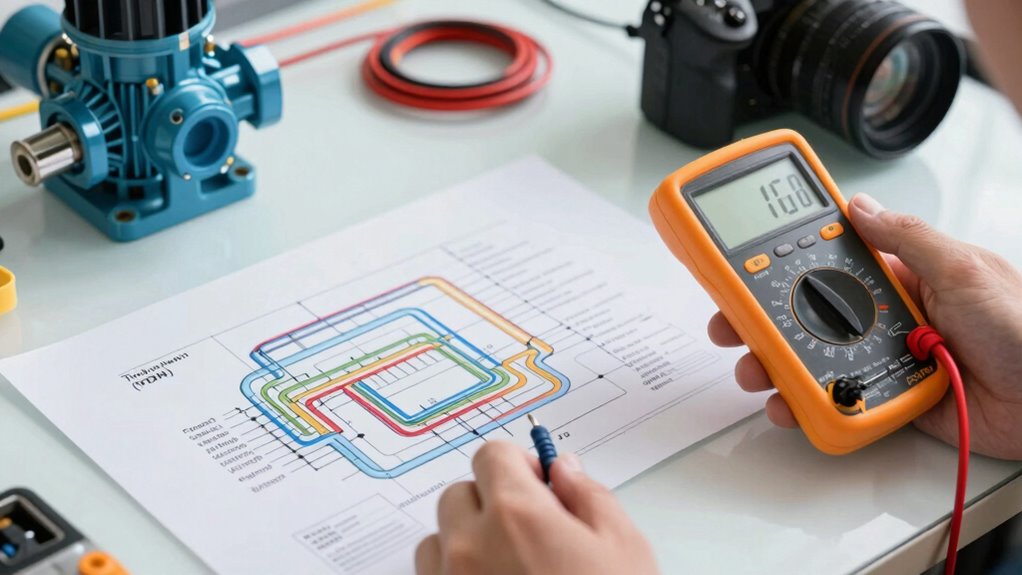

Best Tools and Resources for Calculating TDH

Calculating Total Dynamic Head (TDH) accurately is essential for selecting the right pump, and luckily, several reliable tools and resources can make this process straightforward. For effective pump sizing and system design, digital calculators and software like the Hydraulic Institute’s pump selection tools or industry-specific apps help you determine TDH precisely. These resources allow you to input variables such as flow rate, pipe length, elevation, and friction losses, providing quick, accurate results. Additionally, engineering spreadsheets and online calculators from pump manufacturers simplify the process, especially for complex systems. Using these tools ensures you choose a pump that matches your system’s needs, optimizing performance and efficiency. Staying informed about these resources makes your pump selection process more accurate and less time-consuming.

Tips to Optimize Your System’s Total Dynamic Head

Optimizing your system’s Total Dynamic Head (TDH) can substantially improve pump efficiency and overall performance. To achieve this, focus on proper pump sizing and understanding system hydraulics. Accurate pump sizing ensures the pump matches your system’s flow and pressure needs, reducing energy waste. Improving system hydraulics—such as minimizing pipe friction, eliminating unnecessary fittings, and maintaining clean piping—reduces head losses. Additionally, regularly inspecting and maintaining components prevents issues that increase TDH. Properly balancing system components ensures efficient operation without overburdening the pump. Remember, small adjustments can lead to significant efficiency gains, lowering operating costs and extending equipment lifespan.

Optimizing system hydraulics and pump sizing enhances efficiency and reduces operating costs.

- Select pumps based on precise system calculations

- Minimize pipe length and optimize pipe diameter

- Reduce fittings, valves, and obstructions

- Maintain clean, corrosion-free piping

- Regularly inspect and calibrate system components

Frequently Asked Questions

How Does Temperature Affect Total Dynamic Head Calculations?

Temperature affects total dynamic head calculations because higher temperatures lower fluid viscosity, making it easier for the pump to move the fluid and reducing head requirements. Conversely, thermal expansion causes fluid volume to increase, which can affect flow rates and head calculations. You need to account for these factors because they influence pump performance, ensuring you select a pump that handles temperature variations effectively and maintains system efficiency.

Can TDH Change Over Time in a Pump System?

Yes, TDH can change over time in your pump system. As pump efficiency declines due to wear or corrosion, the total dynamic head increases, affecting performance. Regular system maintenance helps keep efficiency high and prevents unexpected TDH fluctuations. Monitoring these changes allows you to adjust or service the pump, ensuring it operates at its best and maintains consistent flow rates, saving energy and reducing downtime.

What Are Signs of Incorrect TDH Assessment?

If your system’s behaving like a soap opera with flow rate inconsistencies and pressure gauge errors, you’ve likely misjudged your total dynamic head. These signs point to an incorrect TDH assessment, causing your pump to struggle or overwork. Don’t ignore the drama—double-check your measurements and verify your gauges are accurate. Otherwise, you’ll keep starring in a never-ending saga of inefficient performance and costly repairs.

How Do Pipe Diameter and Material Influence TDH?

You should know that pipe diameter and material considerably influence Total Dynamic Head (TDH). A larger pipe diameter reduces friction loss, lowering TDH, while a smaller diameter increases it. Pipe material also matters; smoother materials like PVC decrease friction, while rougher ones like cast iron raise it. Choosing the right pipe diameter and material ensures your pump operates efficiently, preventing overworking or underperformance due to incorrect head calculations.

Is TDH the Same for All Types of Pumps?

No, TDH isn’t the same for all types of pumps. It varies based on pump efficiency and system design. Different pumps are built for specific applications, so their TDH will differ even if they operate in similar conditions. When choosing a pump, you should consider how system design impacts TDH and how pump efficiency affects performance to guarantee ideal operation and longevity.

Conclusion

Understanding total dynamic head is like mastering the heartbeat of your pump system. When you accurately measure and optimize it, you’re tuning a finely crafted instrument that keeps everything flowing smoothly. Don’t let hidden losses or miscalculations drown your efforts—think of TDH as the compass guiding your pump choices. Master it, and you’ll keep your system humming perfectly, turning complex calculations into a symphony of efficiency and performance.