To maintain your booster pump, regularly check pressure gauges and adjust settings to prevent overworking the system. Inspect filters and valves for debris, leaks, or damage, replacing components as needed. Listen for unusual noises or vibrations that could signal problems, and clean and lubricate parts to reduce wear. Schedule professional inspections to catch issues early and keep your system running efficiently. Keep up with these tips to guarantee peak performance and longevity—more useful insights follow.

Key Takeaways

- Regularly inspect pressure gauges, filters, valves, seals, and electrical connections to ensure optimal pump performance.

- Monitor for abnormal noises and vibrations to detect early signs of wear or misalignment.

- Schedule professional maintenance at recommended intervals to verify calibration and replace worn parts.

- Clean and replace filters and check seals to prevent clogs, leaks, and system inefficiencies.

- Address issues promptly to reduce energy costs, extend pump lifespan, and maintain reliable water flow.

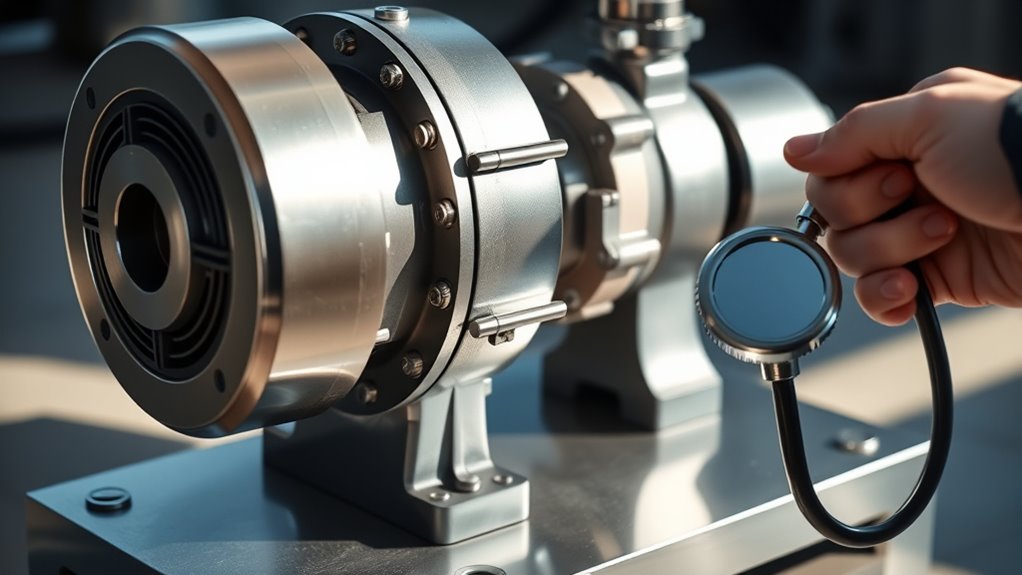

Checking the Pump and Pressure Settings

To guarantee your booster pump operates efficiently, you should regularly check its pump and pressure settings. Proper pressure calibration ensures your system maintains ideal pressure levels, which directly impacts pump efficiency. Start by inspecting the pressure gauge to confirm it matches the recommended settings for your system. If you notice discrepancies, adjust the pressure calibration accordingly. Accurate calibration prevents overworking the pump or causing pressure fluctuations that could damage components. Regularly monitoring these settings helps catch issues early, reducing wear and tear. Keep in mind that maintaining correct pressure levels not only improves performance but also extends the lifespan of your pump. Consistent checks and adjustments are essential steps in ensuring your booster pump runs smoothly and efficiently over time. Understanding keto diet plans can also promote overall health and system performance. Additionally, considering the security of your home’s infrastructure can provide peace of mind while maintaining your equipment. Monitoring system pressure regularly is crucial for optimal operation and longevity of the pump components. Incorporating routine maintenance practices can further enhance the durability and reliability of your system.

Inspecting and Replacing Filters and Valves

After verifying that your pump and pressure settings are correct, it’s important to inspect and maintain the filters and valves. Start with filter replacement if you notice debris or reduced flow; clean or replace filters regularly to prevent clogs. Check the filters for damage or buildup and replace them if necessary. Regular filter maintenance ensures optimal water flow and prevents spoilage, which is essential for filter effectiveness. Additionally, staying informed about credit card security measures can help protect your system from cyber threats. Next, perform valve inspection by examining for leaks, corrosion, or sticking parts. Ensure all valves open and close smoothly, and tighten fittings if needed. Proper filter maintenance keeps water flowing efficiently, while inspecting valves prevents leaks and ensures proper operation. Regularly maintaining filters and valves extends your pump’s lifespan and maintains excellent performance. For example, preventing buildup in filters can significantly improve system longevity. Don’t overlook these simple steps—they’re key to a reliable, trouble-free booster pump system. For optimal operation, regular filter replacement is essential to prevent spoilage and ensure the best performance.

Monitoring for Unusual Noises or Vibrations

Have you noticed any unusual noises or vibrations coming from your booster pump? These signals can indicate underlying issues that need prompt attention. Start with noise diagnosis: loud grinding, knocking, or squealing often points to worn bearings or misaligned components. Vibrations can stem from unbalanced impellers, loose mounting bolts, or damaged motor parts. Pay close attention to when the noises occur—whether during startup, operation, or shutdown—as this can help identify vibration sources. Regularly listen for irregular sounds and feel for unusual vibrations during operation. Addressing these early can prevent more significant failures and costly repairs. Additionally, HEPA filtration can improve the overall performance of air equipment if filters are contaminated or clogged, highlighting the importance of proper maintenance and timely replacements. Proper maintenance practices are essential to ensure the longevity and efficiency of your booster pump and to prevent potential damage caused by overlooked issues. Monitoring for signs like noise and vibrations is a key part of effective preventive maintenance that can save you time and money. Recognizing abnormal equipment behavior early can also help in scheduling timely repairs before major breakdowns occur.

Cleaning and Lubricating Components

Regularly cleaning and lubricating your booster pump’s components is essential for ideal performance. Start by inspecting and wiping down parts to remove dirt and debris, which can compromise seal integrity. Proper lubrication reduces friction on moving parts, preventing wear and extending your pump’s lifespan. Pay close attention to the seals, ensuring they stay moist and intact to prevent leaks. Additionally, check electrical connections for corrosion or looseness, as secure wiring ensures consistent operation. Use the appropriate lubricant recommended by the manufacturer to avoid damage. Keep all components dry and clean, and reassemble carefully. Maintaining pump efficiency through regular upkeep can also help identify potential issues early and keep your system running smoothly. Regular maintenance of these parts not only preserves seal integrity but also ensures reliable electrical connections, minimizing downtime and costly repairs. Incorporating water park maintenance practices can also help identify potential issues early and keep your system running smoothly. Being aware of essential oils for pump maintenance can provide insights into alternative ways to maintain equipment health and performance. Proper documentation of maintenance routines can further enhance system longevity and operational efficiency. Furthermore, utilizing sound healing science principles, such as gentle vibrations during cleaning, may aid in dislodging stubborn debris and enhancing cleaning efficacy.

Scheduling Professional Maintenance and Repairs

Scheduling professional maintenance and repairs is essential to keep your booster pump operating at peak performance and prevent unexpected breakdowns. Regular professional checkups help extend the pump’s lifespan by catching issues early before they escalate. While investing in maintenance might seem like an added expense, it can actually save you money in the long run by avoiding costly repairs or replacements. Skilled technicians can identify wear and tear, ensure proper calibration, and recommend necessary upgrades or parts. Proper appliance diagnostics can help pinpoint problems accurately, saving time and money. Additionally, adhering to a maintenance schedule can help you stay compliant with manufacturer warranties and avoid voiding your coverage. Regular maintenance also promotes energy efficiency, reducing your overall utility costs. Staying proactive with professional service can prevent minor issues from developing into major failures. Implementing a preventive maintenance plan tailored to your specific pump model can further enhance its longevity and performance. Remember, neglecting professional care could lead to decreased performance, higher energy costs, and a shorter pump lifespan—all factors that impact your overall cost considerations.

Frequently Asked Questions

How Often Should I Calibrate My Booster Pump’S Pressure Settings?

You’re wondering about pressure adjustment and calibration frequency for your booster pump. It’s recommended to calibrate your pump’s pressure settings at least once a year, or whenever you notice inconsistent water pressure. Regular calibration guarantees peak performance and prevents potential issues. If your water demand fluctuates or after system repairs, check the pressure adjustment more frequently. Proper calibration keeps your pump running efficiently and extends its lifespan.

What Signs Indicate the Need for a Complete Pump Replacement?

Think of your booster pump as a heartbeat for your system. When it struggles to build pressure, makes unusual noises, or shows inconsistent flow, it’s signaling that its lifespan is nearing an end. Excessive component wear, leaks, or frequent breakdowns also suggest it’s time for a complete replacement. Ignoring these signs can lead to system failure, so trust these signals. Replacing the pump guarantees your system stays healthy and reliable.

Can I Upgrade My Booster Pump for Higher Efficiency?

Upgrading your booster pump can boost efficiency, especially if you’re seeking better performance or lower energy costs. Look for models with improved pump durability and advanced features that enhance efficiency improvements. Consider consulting a professional to guarantee compatibility with your system. An upgrade not only increases reliability but also conserves energy, saving you money long-term. Remember, choosing a high-quality, efficient pump helps optimize your system’s overall performance.

What Safety Precautions Should I Take During Maintenance?

Think of maintenance as your safety dance—every step matters. You should wear personal protective equipment like gloves and goggles to shield yourself from hazards. Before starting, review emergency shutdown procedures so you can act swiftly if needed. Always disconnect the power supply, ensure the pump is depressurized, and follow manufacturer instructions. These precautions keep you safe and prevent accidents during maintenance, making the process smooth and secure.

How Do Environmental Factors Affect Booster Pump Performance?

Environmental factors greatly influence your booster pump’s performance. High humidity or exposure to moisture can cause corrosion, so corrosion prevention becomes crucial. Extreme temperatures may affect the pump’s efficiency, leading to potential overheating or freezing issues. You should regularly inspect your pump for signs of environmental damage, guarantee proper ventilation, and protect it from harsh conditions to maintain ideal operation and extend its lifespan.

Conclusion

By regularly maintaining your booster pump, you’re tending to a crucial heartbeat in your system. When you check the pressure, inspect the filters, and listen closely for odd noises, you’re keeping it alive and humming smoothly. Think of your pump as a trusted companion—when cared for consistently, it’ll serve you tirelessly through every challenge. Keep it clean, lubricated, and well-maintained, and you’ll ensure your system stays resilient, ready to flow effortlessly when you need it most.