Automation sensors for ORP, pH, and temperature are essential for accurately monitoring environmental and process conditions in various industries. They help you maintain ideal process parameters, guarantee compliance, and improve efficiency. Regular calibration and proper maintenance are key to keeping these sensors accurate and reliable over time. With data logging and monitoring features, you can track trends and troubleshoot issues quickly. Keep exploring to discover how these sensors can enhance your operations even further.

Key Takeaways

- Automation sensors for ORP, pH, and temperature enable real-time environmental monitoring in various industries.

- Regular calibration with standard solutions ensures sensor accuracy and reliable measurement data.

- Data logging features facilitate trend analysis, process optimization, and compliance documentation.

- Proper maintenance and calibration are essential to counter environmental factors affecting sensor accuracy.

- Accurate sensor readings support process control, safety measures, and regulatory compliance in automation systems.

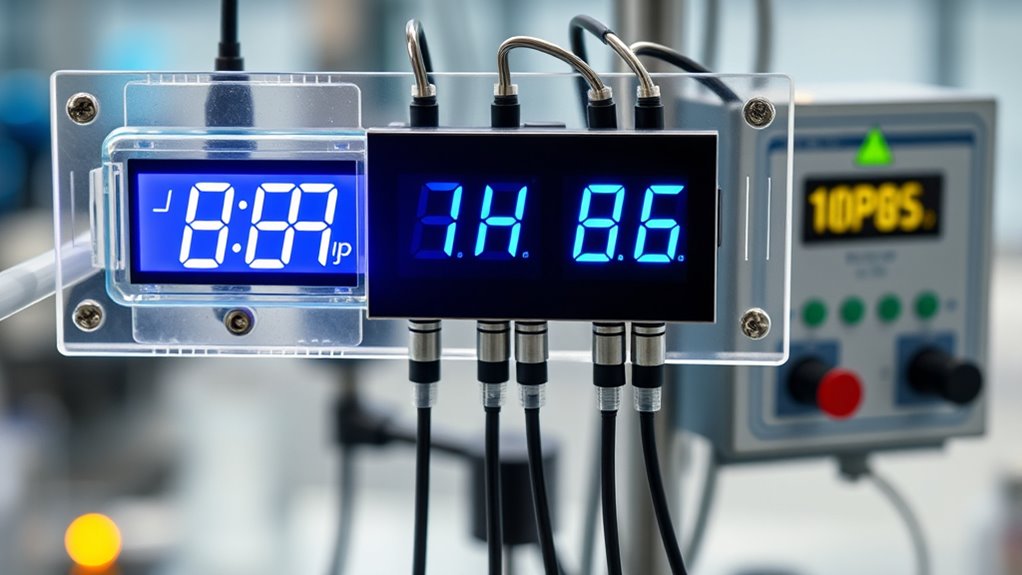

Automation sensors are essential components that enable machines and systems to detect and respond to changes in their environment. When it comes to monitoring parameters like oxidation-reduction potential (ORP), pH, and temperature, these sensors play a crucial role in maintaining optimal conditions across various industries. To guarantee accurate readings, you need to pay close attention to sensor calibration. Proper calibration involves adjusting the sensor outputs to align with known standards, which prevents errors that could compromise your process. Regular calibration not only improves the reliability of your measurements but also extends the lifespan of your sensors. Additionally, many advanced sensors come equipped with data logging capabilities, allowing you to record and analyze measurements over time. This feature is invaluable for tracking trends, troubleshooting issues, and maintaining compliance with industry regulations.

When you’re working with ORP sensors, calibration is particularly vital because even small deviations can significantly impact your control systems. You typically calibrate ORP sensors using standard solutions with known redox potentials, ensuring that the sensor’s readings are accurate. Accurate ORP measurements help you optimize disinfection processes, control chemical dosing, and monitor water quality effectively. For pH sensors, calibration usually involves using buffer solutions at specific pH levels, which helps maintain precise pH control in applications like water treatment, food processing, or laboratory analysis. Proper calibration ensures that your pH readings truly reflect the actual conditions, enabling you to make informed decisions promptly. It is also important to consider the sensor environment, as factors like temperature and contamination can affect measurement accuracy.

Temperature sensors, on the other hand, require calibration against certified temperature standards to guarantee accuracy. Since temperature influences many chemical and biological processes, precise measurement is vital. Many sensors offer data logging, so you can track temperature fluctuations over time, which is especially useful for audits or process optimization. When sensors are properly calibrated and their data is logged consistently, you gain a comprehensive understanding of your system’s behavior, helping you prevent failures, reduce waste, and improve overall efficiency.

Frequently Asked Questions

How Do Automation Sensors Improve Water Quality Control?

Automation sensors improve water quality control by providing real-time, accurate data on parameters like ORP, pH, and temperature. Their sensor accuracy guarantees you get reliable readings, allowing for quick adjustments. Data integration from these sensors streamlines monitoring processes, reducing manual work and errors. This proactive approach helps maintain ideal water conditions, preventing issues before they escalate, ultimately ensuring safer, cleaner water for consumers or processes.

What Maintenance Is Required for ORP Sensors?

You need to stay on top of ORP sensor maintenance, or you’ll find yourself in hot water. Regular calibration, typically every few weeks, ensures accuracy, while monitoring sensor lifespan helps you identify when replacement is due. Keep the sensor clean and protected from fouling, and check connections regularly. Proper maintenance minimizes downtime and keeps your water quality control precise, so your system runs smoothly without surprises.

Can Ph Sensors Be Calibrated Remotely?

Yes, you can perform remote calibration of pH sensors to guarantee sensor accuracy. Many modern systems allow you to access calibration functions remotely through network connections or software interfaces. By doing this, you can maintain ideal sensor performance without on-site visits. Regular remote calibration helps you detect drifts in sensor accuracy early, reducing downtime and ensuring reliable pH measurements in your monitoring system.

How Do Temperature Sensors Affect Process Efficiency?

Think of temperature sensors as the thermostat for your process. When properly calibrated, they guarantee accurate readings, helping you optimize efficiency. Accurate sensors improve data integration, allowing seamless adjustments and reducing waste. If calibration drifts, it’s like a thermostat stuck on high or low, causing inefficiency. Regular sensor calibration keeps your temperature data reliable, so you can make informed decisions, maximize productivity, and maintain process consistency.

Are Automation Sensors Compatible With Existing Systems?

Yes, automation sensors are generally compatible with existing systems, but you should consider sensor integration and compatibility considerations first. Check if your current equipment supports the sensor types you want to add, and confirm communication protocols like Modbus or HART. You might need adapters or software updates to guarantee seamless integration. Doing this ensures your sensors work efficiently within your system, improving monitoring accuracy and process control.

Conclusion

Now that you understand how ORP, pH, and temperature sensors keep your automation systems precise, imagine what could happen if one of these sensors fails silently. Will you be prepared to catch the signs before it’s too late? Staying vigilant with regular checks might just be the difference between smooth operation and unexpected downtime. Don’t wait for a crisis—stay ahead and keep your automation running flawlessly. The future of your system depends on what you do next.